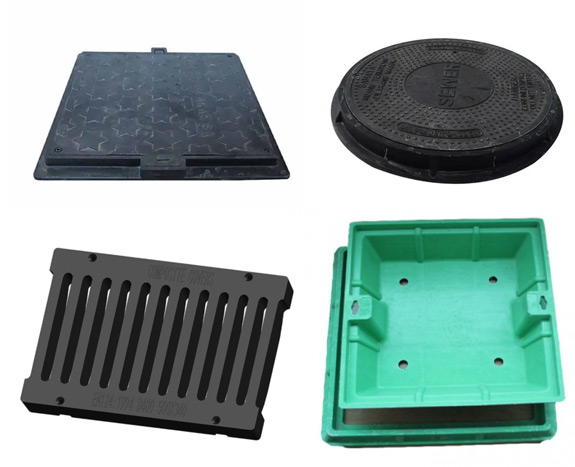

SMC Composite Manhole Covers, Round Plastic Manhole Cover, Smc Composite Manhole Cover, Hinged Manhole Cover,Composite Drainage Board.

The SMC manhole cover is a dry molding compound for the manufacture of unsaturated polyester FRP products. It is based on the benzene-type unsaturated polyester resin as the main raw material, adding reinforcing materials and auxiliary materials, and through the scientific formula and the new process.

The Avatarsmc composite has no recycling value, greatly reducing the chance of theft compared to the iron casting manhole cover. The weight of the product is much lighter than that of cast iron, which greatly reduces the damage of the human spine and fingers during the installation process, while the surface has a good anti-slip design.

Clear opening 900mm(35") FRP manhole cover for Petrol Station.

The heavy duty manhole covers are suitable for installation within Heavy Goods Vehicles trafficked areas such as the tanker delivery area.

Clear opening 900mm (35")with inspection hole FRP manhole cover are specially for Petrol Stations.

The covers are suitable for installation within Heavy Goods Vehicle trafficked areas such as the tanker delivery area.

500mm FRP D400 Grating and Frame with FRP composite material.